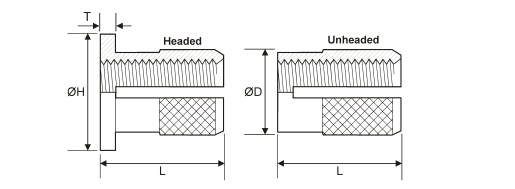

Brass Knurling Inserts

The surface design of Brass Knurling Inserts is distinctive and enhances grip and fastening security. Using press fit and ultrasonic installation techniques, they are easy to install.

Application stability is provided to varied degrees by each type of knurled insert. While diamond knurling is more forceful and suited for applications that call for a stronghold, straight knurling is excellent for a straightforward grip.

In situations where the grip may only be in one direction, unidirectional knurling is employed. While concentric knurling is necessary for consistent grip, crossed knurling is great for stability.

The automobile, electronics, laptop, plastic molding, and aerospace sectors all employ brass knurling insert extensively.

Kaizen Metals Products Range

Brass Straight Knurling inserts, Brass Diamond Knurling, Brass Unidirectional knurling Inserts, Brass Cross Knurling Inserts, Brass Concentric Knurling Inserts, Brass Press-fit Inserts, Brass Double Knurling Inserts, Brass Self-Tapping Inserts, Brass Heat-set Inserts.

Brass Knurling Inserts Description

Materials:

Brass Alloy: CuZn39Pb3 / CuZn39Pb2 / CuZn38Pb1.5 / CuZn37Pb2 / CuZn40Pb2 / MS 58 / BS2874 / IS 319 (Type I & II)

UNS (ASTM): C35300 / C35330 DZR / C36000 (CDA 360) / C36500 / C37000 / C37100 / C37700 / C37710 / C38500

BS: CZ121 / CZ122 / CZ124 / CZ128 / CZ 131 / CZ132

EN: CW602N / CW603N / CW606N / CW608N / CW612N / CW614N / CW617N

JIS: C3601 / C3602 / C3603 / C3604 / C3605 / C3712 / C3771

Any special brass material compositions as per customer’s requirements.

- Custom design accepted.

- Design as customer’s requirements offered.

- Free sample before manufacturing provided.

Sample Time: Available in 5-10 days for different items.

Drawing Format: CAD / PDF / DWG / IGS / STEP.

Packaging: Standard package, Carton box or Pallet, As per customized specifications

Shipping: DHL, FEDEX, UPS and By Sea or as per client’s requirements.