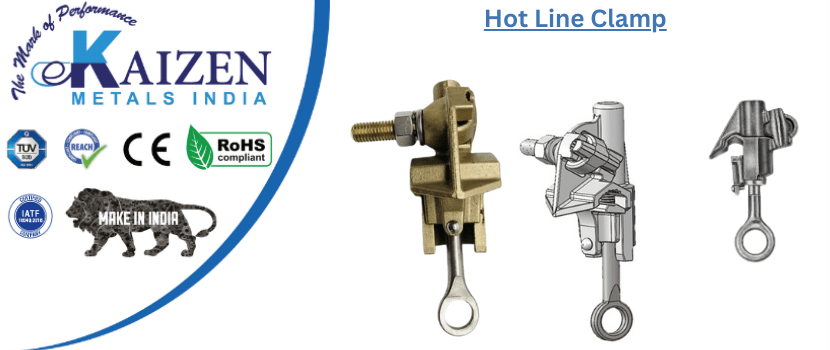

Hot Line Clamps

Hot line clamps assume a critical part in the electrical business by giving a solid association among transmitters and electrical parts.

They are intended to endure high temperatures and proposition superb electrical conductivity, making them a fundamental piece of force transmission and circulation frameworks.

Hot line braces are utilized to associate channels and electrical parts in power transmission and dispersion frameworks.

They give a solid and dependable association that can endure high temperatures and unforgiving conditions.

What are the various sorts of hot line cinches?

There are a few sorts of hot line cinches accessible, including aluminum, copper, and bronze braces.

Every material offers remarkable benefits, so picking the material that best suits your application is fundamental.

What elements ought to be thought about while choosing hot line cinches?

Significant elements to consider while choosing hot line braces incorporate material, conductivity, sturdiness, and simplicity of establishment.

It is additionally essential to guarantee the clip is viable with the guide types utilized in your framework and is appropriately estimated for your application.

What are the benefits of obtaining hot line braces from Kaizen Metals india?

Kaizen Metals india offers great hot line clasps produced using premium materials, cutthroat evaluating, and master direction and backing from our educated group.

We are focused on giving excellent client care and conveying top-quality items that satisfy and surpass industry guidelines.

Indeed, Kaizen Metals india offers custom hot line clips to meet the extraordinary necessities of our clients.

If it’s not too much trouble, contact our outreach group for more data.

Types of Hot Line Clamps

There are several types of hot line clamps available on the market, including:

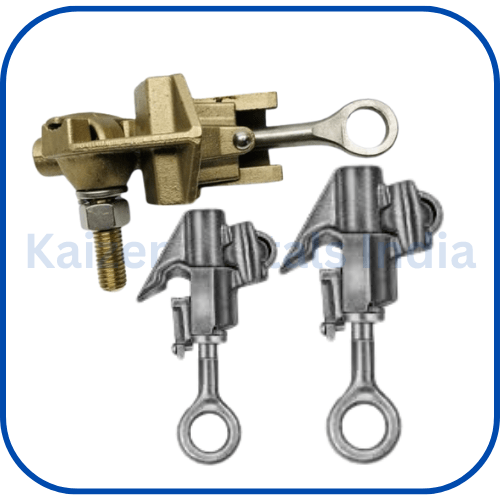

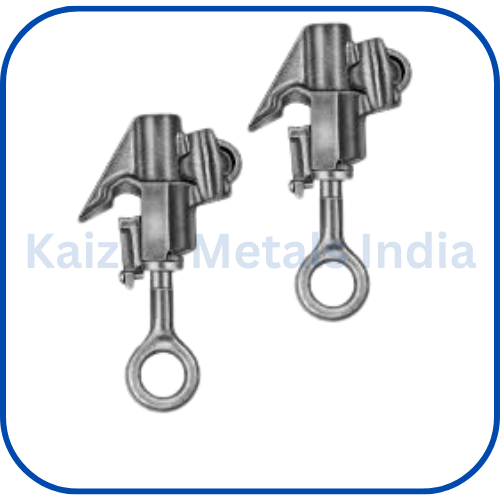

- Aluminum hot line clamps: These clamps are lightweight and provide excellent corrosion resistance. They are ideal for use in areas with high humidity or exposure to saltwater.

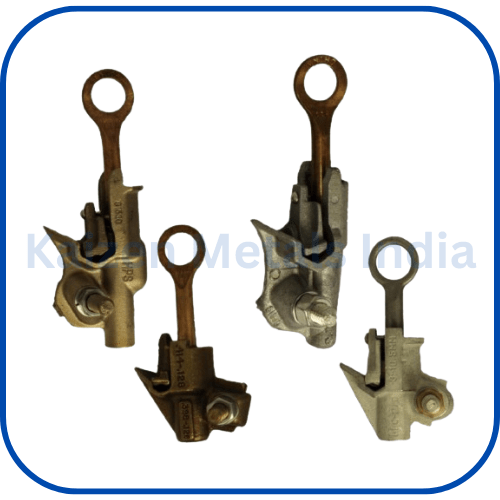

- Copper hot line clamps: Copper clamps offer high electrical conductivity and are widely used in the electrical industry. They are resistant to corrosion and are suitable for use in various environmental conditions.

- Bronze hot line clamps: Bronze clamps are made from a combination of copper and other alloying elements, providing a balance between electrical conductivity and corrosion resistance. They are durable and suited for heavy-duty applications.

Key Features of Hot Line Clamps

- Durability: Hot line clamps are made from high-quality materials to ensure they can withstand the harsh environments they are exposed to, such as high temperatures, humidity, and corrosive elements.

- Corrosion resistance: The clamp’s material is resistant to corrosion to maintain its structural integrity and provide a long service life.

- Conductivity: A hot line clamp’s electrical conductivity is essential for maintaining a reliable connection between conductors. The clamp material has high electrical conductivity to minimize power loss.

- Ease of installation: Hot line clamps are easy to install and maintain, as this can help reduce labor costs and minimize downtime during maintenance.

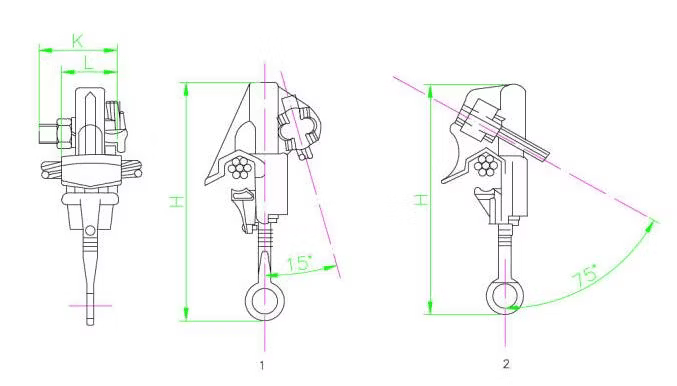

Aluminum Alloy Hot Line Tap Connector Clamp

Application:

Hot line tap clamp is used for non-load-bearing connections and branches of conductors in overhead power lines.

Features:

Installation:

Choosing the Right Hot Line Clamp

To choose the right hot line clamp for your specific application, consider the following factors:

- Material considerations: The clamp’s material should be selected based on its intended application and environment. Aluminum, copper, and bronze clamps each have their unique advantages, so it’s essential to choose the material that best suits your needs.

- Compatibility with conductor types: Ensure that the hot line clamp you select is compatible with the conductor types used in your system. This includes considering the conductor’s size, material, and other properties.

- Proper sizing: Selecting the correct size of a hot line clamp is crucial for maintaining a secure connection between conductors. It is essential to choose a clamp that fits the conductor size and can accommodate any thermal expansion or contraction that may occur during operation.

Sample Time: Available in 5-10 days for different items.

Drawing Format: CAD / PDF / DWG / IGS / STEP.

Packaging: Standard package, Carton box or Pallet, As per customized specifications

Shipping: DHL, FEDEX, UPS and By Sea or as per client’s requirements.