Brass Lock Washers

We provide a large selection of Brass lock washers that are made with excellent stainless steel and other raw materials. These washers have good chemical resistance and less friction.

Our customers may choose from a large selection of Quick Lock Washers from us, which are frequently utilized in loading applications with constrained radial space.

These are frequently employed in electrical and technical applications and conduct the locking action against rotation of the screw of bolted assemblies.

We are recognized as one of the reputable companies engaged in providing a unique selection of Lock Washers utilized in many industries.

Our vendor’s agile specialists use premium raw materials and cutting-edge technology to produce the washers we provide.

Provided washers, which are readily available in a variety of designs and conditions, are highly demanded in the industry. Additionally, we provide the whole range at the most reasonable prices.

In fastener assemblies, brass washers are frequently used to distribute loads uniformly and provide structural stability.

Once fitted, they assist maintain tension that may be lost as a result of vibrations and guard against over-tightening, damage to the installation material, and over tightening.

- In order to ensure that a lock to prevent unscrewing works properly, the hardness of the mating material must be lower than that of the washer.

- A maximum pretension loss of 20% is only to be expected as a result of creep and settling.

- Brass Washers are therefore defined as locks against unscrewing.

- Locks against unscrewing, with both higher and lower pretensioning.

- With narrow and wide contact surfaces.

- Very easy mounting and removal (wedge lock washers are already bonded in pairs).

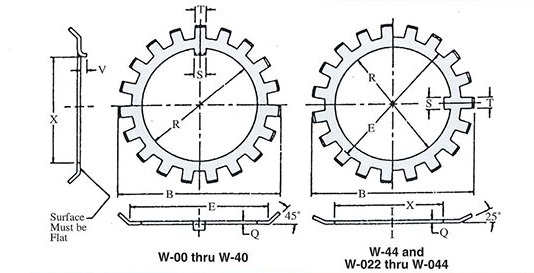

Brass Lock Washers Description

- Material: 360 Brass, Any Standard Brass as per custom specification.

- Manufacturing Process: Machining, Forming, Thread Production, Heat Treatment.

- Surface Plating: Copper Plating, Nickel Plating, Chrome Plating, Electro Plating, Mechanically Galvanized Coating, Hot dip Galvanising.

- Conformal Standards: IEC 61219, ASTM B687 – 99, DIN Standards.

- Threads: Metric Coarse, Metric Fine, UNC, DIN, GB, UNF, BSW, BSF and BA.

Sample Time: Available in 5-10 days for different items.

Drawing Format: CAD / PDF / DWG / IGS / STEP.

Packaging: Standard package, Carton box or Pallet, As per customized specifications

Shipping: DHL, FEDEX, UPS and By Sea or as per client’s requirements.