- October 9, 2023

- by Kaizen

- Brass Nut, Fasteners and Fixing

What is Hex Lock Nut? Dimensions, Properties and Uses

Whats is Hex lock nuts are significant fasteners that are used in a variety of settings. They are made especially to strengthen the security of threaded fasteners and guard against loosening. Understanding hex lock nuts is crucial for effective installation and optimum equipment operation, whether you’re an industrial producer, a maintenance professional, or a DIY enthusiast. The dimensions, characteristics, and applications of hex lock nuts will be covered in this blog article.

What is Hex Lock Nut?

A hex lock nut is a type of fastener used in industrial and automotive applications. It is sometimes referred to as a jam nut or a hexagon thin. Six sides enhance the surface area of contact, locking pieces with more torque than standard nuts. When necessary for vibration isolation or to prevent tampering and loosening, it is frequently utilized. To meet different purposes, these nuts are offered in a variety of sizes and construction types.

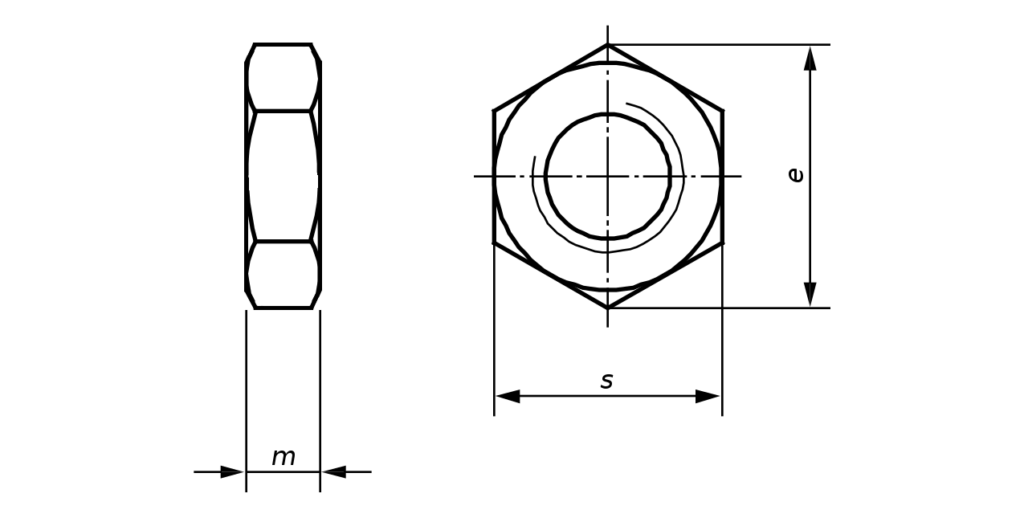

Hex Lock Nut Dimensions

| Diameter | Pitch | Depth of Nut | Across Flats |

| M2 | 0.4mm | 1.2mm | 4.0mm |

| M2.5 | 0.45mm | 1.6mm | 5.0mm |

| M3 | 0.5mm | 1.8mm | 5.5mm |

| M4 | 0.7mm | 2.2mm | 7mm |

| M5 | 0.8mm | 2.7mm | 8mm |

| M6 | 1.0mm | 3.2mm | 10mm |

| M8 | 1.25mm | 4.0mm | 13mm |

| M10 | 1.5mm | 5mm | 17mm |

| M12 | 1.75mm | 6mm | 19mm |

| M14 | 2mm | 7mm | 22mm |

| M16 | 2mm | 8mm | 24mm |

| M18 | 2.5mm | 9mm | 27mm |

| M20 | 2.5mm | 10mm | 30mm |

| M22 | 2.5mm | 11mm | 32mm |

| M24 | 3.0mm | 12mm | 36mm |

| M27 | 3.0mm | 13.5mm | 41mm |

| M30 | 3.5mm | 15mm | 46mm |

| M33 | 3.5mm | 16.5mm | 50mm |

| M36 | 4mm | 18mm | 55mm |

| M39 | 4mm | 19.5mm | 60mm |

| M42 | 4.5mm | 21mm | 65mm |

| M45 | 4.5mm | 22.5mm | 70mm |

| M48 | 5mm | 24mm | 75mm |

| M52 | 5mm | 26mm | 80mm |

| M56 | 5.5mm | 28mm | 85mm |

| M60 | 5.5mm | 30mm | 90mm |

Hex Lock Nut Properties

Hex lock nuts are the ideal choice for a variety of applications since they have a variety of characteristics. Vibration resistance, high torque, and loosening are a few of these. The tapered form of hex lock nuts produces tension between the nut and bolt to stop unauthorized movement. Additionally, they are frequently coated with a variety of compounds to fend off corrosion and environmental harm.

Hex Lock Nut Uses

Hex lock nuts have several uses, including in the automotive, aerospace, electrical, and plumbing industries. They are frequently utilized in engines, generators, and heavy-duty construction gear and equipment, all of which have significant vibration levels. Additionally, they are utilized in settings like airplane engines, bridges, and towers where safety is crucial.

Hex Lock Nut Installation

Hex lock nut installation is a straightforward procedure that only needs a few simple instruments. Make sure the threaded bolt or screw fits the nut properly in terms of size and form. Use a wrench or pair of pliers to screw in the appropriate nut and tighten it. To secure the nut, use moderate effort, but be careful not to overtighten as this might weaken the joint and damage the threads.

Hex Lock Nut Maintenance

Hex lock nuts need very little upkeep to function at their best. Particularly if the equipment is utilized in difficult environmental conditions, routine examination is required. Look for any corrosion, damage, or loosening indicators. Replace the nut right away if you find any problems to stop additional harm.

Conclusion:

Hex lock nuts are crucial fasteners in many applications because they create strong and dependable couplings. They are excellent for a variety of applications since they have a wide range of sizes, dimensions, and other characteristics. Hex lock nuts are simple to install and don’t require any upkeep. Select the proper size and substance for hex lock nuts if you intend to use them on your machinery or equipment for optimum performance.