- October 7, 2023

- by Kaizen

- Brass Washer, Fasteners and Fixing

What is SAE Flat Washer? Dimensions, Properties and Uses

The SAE Flat Washer is one of the most often utilized parts when it comes to bolting and fastening. Even though it appears easy and uncomplicated, different washer kinds have distinct uses.

The SAE flat washer is one type of this. This blog post will go through the characteristics, functions, and usage of SAE flat washers.

What is SAE Flat Washer?

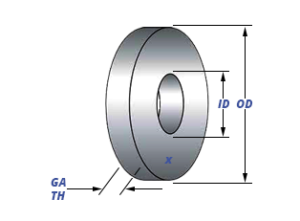

Metal discs called SAE Flat Washers have a hole in the middle and a circular outside diameter. They are used to more effectively prevent looseness by distributing a fastener’s load across a surface. Outside diameters of SAE (Society of Automotive Engineers) flat washers normally range from 0.25′′ to 3′′, and they are available with either imperial or metric thread sizes. Cutting assembly costs by avoiding marring, galling, and corrosion brought on by direct screw-to-metal contact between two surfaces is one of the main advantages of utilizing SAE flat washers.

SAE Flat Washer Dimensions

| SAE Low Carbon & Stainless Washers | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Bolt Size Click on the size to shop products | Outside Diameter (OD) | Inside Diameter (ID) | Thickness (TH) | Approx. number of STEEL washers per carton | |||||||

| Nominal | Max | Min | Nominal | Max | Min | American Standard (Gauge) | Max | Min | 50 Lbs. (Zinc, Black Oxide or Plain finish) | 20 Lbs. (Galvanized) | |

| 4 | 5/16 | 0.320 | 0.307 | 1/8 | 0.133 | 0.120 | (1/32) | .040 | .025 | 83300 | – |

| 6 | 3/8 | 0.390 | 0.370 | 5/32 | 0.164 | 0.151 | 18 (3/64) | .065 | .036 | 39500 | – |

| 8 | 7/16 | 0.453 | 0.433 | 3/16 | 0.196 | 0.183 | 18 (3/64) | .065 | .036 | 29500 | – |

| 10 | 1/2 | 0.515 | 0.495 | 7/32 | 0.227 | 0.214 | 18 (3/64) | .065 | .036 | 22750 | – |

| 3/16 | 9/16 | 0.577 | 0.557 | 1/4 | 0.265 | 0.245 | 18 (3/64) | .065 | .036 | – | – |

| 12 | 9/16 | 0.577 | 0.557 | 1/4 | 0.265 | 0.245 | 16 (1/16) | .080 | .051 | 14700 | – |

| 1/4 | 5/8 | 0.640 | 0.620 | 9/32 | 0.296 | 0.276 | 16 (1/16) | .080 | .051 | 11100 | 4440 |

| 5/16 | 11/16 | 0.703 | 0.681 | 11/32 | 0.359 | 0.339 | 16 (1/16) | .080 | .051 | 9750 | 3900 |

| 3/8 | 13/16 | 0.827 | 0.805 | 13/32 | 0.419 | 0.401 | 16 (1/16) | .080 | .051 | 7000 | 2800 |

| 7/16 | 59/64 | 0.937 | 0.915 | 15/32 | 0.484 | 0.464 | 16 (1/16) | .080 | .051 | 5500 | – |

| 1/2 | 1-1/16 | 1.092 | 1.055 | 17/32 | 0.546 | 0.526 | 13 (3/32) | .121 | .074 | 2800 | 1120 |

| 9/16 | 1-3/16 | 1.186 | 1.149 | 19/32 | 0.609 | 0.589 | 13 (3/32) | .121 | .074 | 2250 | – |

| 5/8 | 1-5/16 | 1.342 | 1.305 | 21/32 | 0.686 | 0.649 | 13 (3/32) | .121 | .074 | 1850 | 722 |

| 3/4 | 1-1/2 | 1.499 | 1.462 | 13/16 | 0.842 | 0.805 | 10 (9/64) | .160 | .108 | 1050 | 337 |

| 7/8 | 1-3/4 | 1.780 | 1.743 | 15/16 | 0.968 | 0.931 | 10 (9/64) | .160 | .108 | 775 | – |

| 1 | 2 | 2.030 | 1.993 | 1-1/16 | 1.092 | 1.055 | 10 (9/64) | .160 | .108 | 585 | – |

| 1-1/8 | 2-1/4 | 2.280 | 2.243 | 1-3/16 | 1.280 | 1.243 | 10 (9/64) | .160 | .108 | 460 | – |

| 1-1/4 | 2-1/2 | 2.530 | 2.493 | 1-5/16 | 1.405 | 1.368 | 9 (5/32) | .192 | .136 | 335 | – |

| 1-3/8 | 2-3/4 | 2.780 | 2.743 | 1-7/16 | 1.530 | 1.493 | 9 (5/32) | .213 | .136 | 275 | – |

| 1-1/2 | 3 | 3.030 | 2.993 | 1-9/16 | 1.655 | 1.618 | 9 (5/32) | .213 | .153 | 230 | – |

SAE Flat Washer Properties

Depending on the purpose, numerous materials can be used to make SAE flat washers. Steel, stainless steel, and brass are the most often utilized materials. While stainless steel washers are corrosion-resistant, steel washers are often zinc-plated to prevent rust. The integrity and safety of the fastening connection are guaranteed by the manufacturing of SAE flat washers, which are made to last and endure severe pressure and vibration.

SAE Flat Washer Benefits

There are several advantages to using SAE flat washers. They firstly offer a dependable and uniform load distribution, which can aid in preventing fastener failure brought on by overloading or underloading. In addition, they can shield the surface from harm from the fastener or the object it is fastened to. Thirdly, the performance and longevity of the fastening joint can be improved by employing washers with the suitable size and characteristics.

SAE Flat Washer Uses

Applications for SAE flat washers include the mechanical, automotive, building, and electrical sectors. The danger of damage to the fastening joint and the surface it is fastened to is decreased thanks to these washers’ assistance in distributing loads and pressure equally throughout the surface. In order to fill gaps or correct misalignments between the fastening surfaces, they can also serve as spacers or shims.

Conclusion:

SAE flat washers are essential in bolting and fastening applications, to sum up. They provide advantages such uniform load distribution, surface protection, and increased performance and are available in conventional sizes, materials, and thicknesses. SAE flat washers are made to handle tremendous pressure and vibrations, whether they are used in vehicles, machinery, or construction equipment. This guarantees the security and integrity of the fastening joint. The washers’ lifespan may be increased and their maximum performance maintained with proper storage and maintenance.